High-definition CNC cutters have revolutionized the metal business industry, providing a multitude of benefits for entrepreneurs in this field. These state-of-the-art machines elevate precision and accuracy to unprecedented levels, enabling the creation of intricate and complex designs with remarkable ease.

However, the advantages of High-quality CNC Cutters extend far beyond impeccable cuts. They offer enhanced efficiency, material versatility, and even cost savings. In this discussion, we will delve into these advantages in detail, uncovering how high-definition CNC cutters empower metal business entrepreneurs to excel in their craft and stay ahead in an ever-evolving market.

Key Takeaways

- High-Definition CNC Cutters offer enhanced precision and accuracy in metalworking processes, allowing for the creation of intricate and complex designs.

- These machines increase efficiency and productivity by automating and streamlining the metal cutting process, resulting in minimal material waste and faster turnaround times.

- High-quality CNC Cutters enable metal business entrepreneurs to customize their products and explore new shapes, textures, and forms, giving them a competitive edge in the market.

- These machines contribute to cost savings by reducing material wastage and enhancing workplace safety through their automated nature.

Understanding High-Definition CNC Cutters

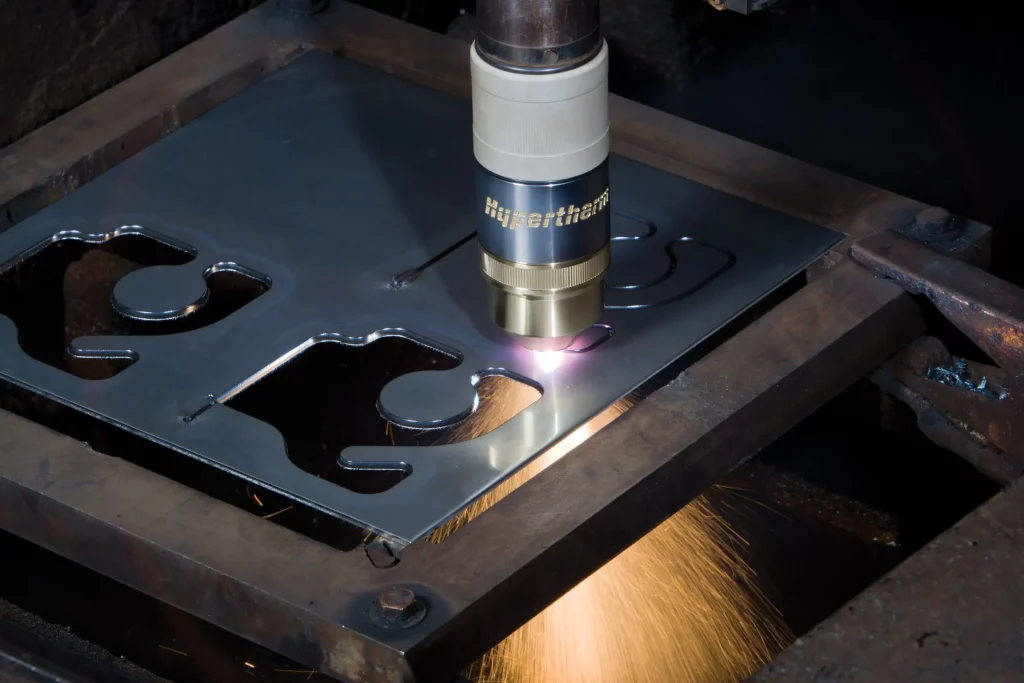

High-Definition CNC Cutters, also known as Computer Numerical Control Cutters, are advanced precision cutting machines used in the metalworking industry. These machines utilize computer-controlled movements to accurately cut and shape various materials, including metals, with high precision and efficiency.

One of the key advantages of High-quality CNC Cutters is their ability to produce intricate and complex designs with utmost precision. The computer-controlled system allows for the creation of intricate patterns, curves, and shapes that would be difficult to achieve manually. This level of precision ensures that the final product meets the exact specifications and requirements of the customer.

Furthermore, best-quality CNC Cutters offer enhanced efficiency and productivity compared to traditional cutting methods. The automated nature of these machines allows for continuous and uninterrupted cutting operations, reducing the time required to complete a job. Additionally, the advanced technology used in these cutters ensures minimal material wastage, optimizing the use of resources.

In addition to their precision and efficiency, High-quality CNC Cutters also offer improved safety features. These machines are equipped with safety sensors and emergency stop buttons to prevent accidents and injuries. The use of computer controls also eliminates the need for manual handling of sharp tools, reducing the risk of operator injuries.

Enhancing Precision and Accuracy

With their advanced computer-controlled system, High-Definition CNC Cutters excel in enhancing precision and accuracy in metalworking processes. These cutting-edge machines offer several features that contribute to their ability to achieve precise and accurate results:

- High-resolution imaging: Best-Definition CNC Cutters utilize advanced imaging technology to capture detailed images of the workpiece. This high-resolution imaging allows for accurate detection of the material’s shape, size, and position, ensuring precise cutting.

- Real-time monitoring: These CNC Cutters are equipped with real-time monitoring systems that continuously track the cutting process. This monitoring allows operators to make immediate adjustments if any deviations or errors are detected, ensuring the final product meets the desired specifications.

- Fine-tuned control: High-quality CNC Cutters provide fine-tuned control over the cutting process. Operators can adjust various parameters, such as cutting speed, depth, and angle, with great precision. This level of control ensures that the cuts are made accurately and consistently, resulting in high-quality finished products.

- Automated calibration: These CNC Cutters feature automated calibration systems that ensure the machine is always properly aligned and calibrated. This eliminates the risk of human error and guarantees that the cuts are made with utmost precision.

Increasing Efficiency and Productivity

To maximize operational effectiveness, Best-Definition CNC Cutters offer significant advantages in terms of efficiency and productivity for metal business entrepreneurs. These advanced cutting machines utilize computer numerical control (CNC) technology to automate and streamline the metal cutting process. By eliminating manual labor and human error, High-quality CNC Cutters can greatly enhance the efficiency of metal fabrication operations.

One key advantage of best-quality CNC Cutters is their ability to perform complex cuts with precision and speed. The CNC control system allows for highly accurate and repeatable cutting, resulting in minimal material waste and increased productivity. Additionally, the high-definition plasma cutting technology used in these machines ensures clean, smooth cuts, reducing the need for secondary finishing processes.

Furthermore, High-quality CNC Cutters offer a wide range of customizable features and options. Operators can easily program the machine to execute specific cutting patterns and designs, allowing for increased flexibility and productivity. The machines can also be equipped with advanced nesting software, which optimizes material usage and minimizes scrap, further improving efficiency.

Expanding Design Possibilities

Best-Definition CNC Cutters offer metal business entrepreneurs a wide range of design possibilities. With their precise cutting capabilities, these advanced machines enable the creation of intricate and complex designs that were once difficult or impossible to achieve.

Here are some of the ways in which High-quality CNC Cutters can expand design possibilities:

- Intricate Patterns: Best-Definition CNC Cutters can accurately cut intricate patterns into metal sheets, allowing for the creation of visually stunning designs. From delicate filigree to intricate geometric shapes, these machines can bring even the most complex designs to life.

- Customization: With High-quality CNC Cutters, metal business entrepreneurs can easily customize their products to meet the specific needs and preferences of their customers. These machines can cut precise shapes, letters, and logos, enabling businesses to create personalized designs that resonate with their target audience.

- Versatility: Best-quality CNC Cutters can cut a wide variety of metals, including stainless steel, aluminum, and brass. This versatility opens up endless design possibilities, as entrepreneurs can experiment with different materials to create unique and eye-catching designs.

- Repetition: Best-quality CNC Cutters excel at creating consistent and precise cuts, making them ideal for mass production. Entrepreneurs can easily replicate designs, ensuring a consistent and high-quality product every time.

- Innovation: With High-quality CNC Cutters, entrepreneurs can push the boundaries of traditional metal design. These machines allow for the exploration of new shapes, textures, and forms, enabling businesses to stay at the forefront of design innovation and stand out in a competitive market.

Gaining a Competitive Edge

Gaining a competitive edge in the metal business industry requires leveraging the advantages of best-Definition CNC Cutters. These cutting-edge machines offer numerous benefits that can give metal business entrepreneurs the upper hand in a highly competitive market.

One advantage of best-Definition CNC Cutters is their ability to produce intricate and precise cuts. With their advanced technology and high-resolution cutting capabilities, these cutters can create complex designs and shapes with utmost accuracy. This precision allows metal business entrepreneurs to offer unique and customized products that stand out from the competition.

Furthermore, b-Definition CNC Cutters offer increased efficiency and productivity. Their automated processes and fast cutting speeds enable metal businesses to complete projects in a shorter amount of time, leading to increased productivity and faster turnaround times. This efficiency not only helps meet customer demands promptly but also allows entrepreneurs to take on more projects and expand their business.

In addition, High-quality CNC Cutters ensure consistent quality in every cut. The accuracy and precision of these machines guarantee that each piece produced is of the highest standard. This reliability helps build a reputation for excellence, attracting more customers and establishing a loyal customer base.

Frequently Asked Questions

What Is the Cost of High-Definition CNC Cutters for Metal Business Entrepreneurs?

The cost of high-definition CNC cutters for metal business entrepreneurs can vary depending on the specific model and features required. Factors such as machine size, cutting capabilities, and additional accessories can all contribute to the overall cost.

Can High-Definition CNC Cutters Be Used for Materials Other Than Metal?

Yes, high-definition CNC cutters can be used for materials other than metal. These advanced machines are capable of cutting a wide range of materials, including wood, plastic, and composites, with precision and efficiency.

Are There Any Additional Training or Skills Required to Operate High-Definition CNC Cutters?

Yes, operating high-definition CNC cutters requires additional training and skills. These machines are complex and precise, requiring operators to have a good understanding of computer programming, CAD software, and machine operation to ensure accurate and efficient cutting processes.

How Does the Use of High-Definition CNC Cutters Impact the Overall Quality of the Finished Products?

The use of high-definition CNC cutters significantly improves the overall quality of finished metal products. These precision machines offer superior accuracy and finer details, resulting in smoother edges, tighter tolerances, and enhanced surface finishes.

Can High-Definition CNC Cutters Be Integrated With Existing Manufacturing Processes?

Yes, high-quality definition CNC cutters can be integrated with existing manufacturing processes. Their advanced technology allows for precise and efficient metal cutting, improving overall production quality and reducing costs for metal business entrepreneurs.

Conclusion

In conclusion, high-definition CNC cutters offer metal business entrepreneurs the advantage of precise and accurate cutting, resulting in superior finished products. These machines also enhance efficiency and productivity, reducing production time and increasing profitability. Moreover, their versatility allows entrepreneurs to expand their offerings and cater to a wider range of customer needs. With their cost-saving capabilities and ability to provide a competitive edge in the market, best-definition CNC cutters are indispensable tools in the metal industry.

You May Also Like: